Battery Pack Assembly

Author: Alex Doknjas

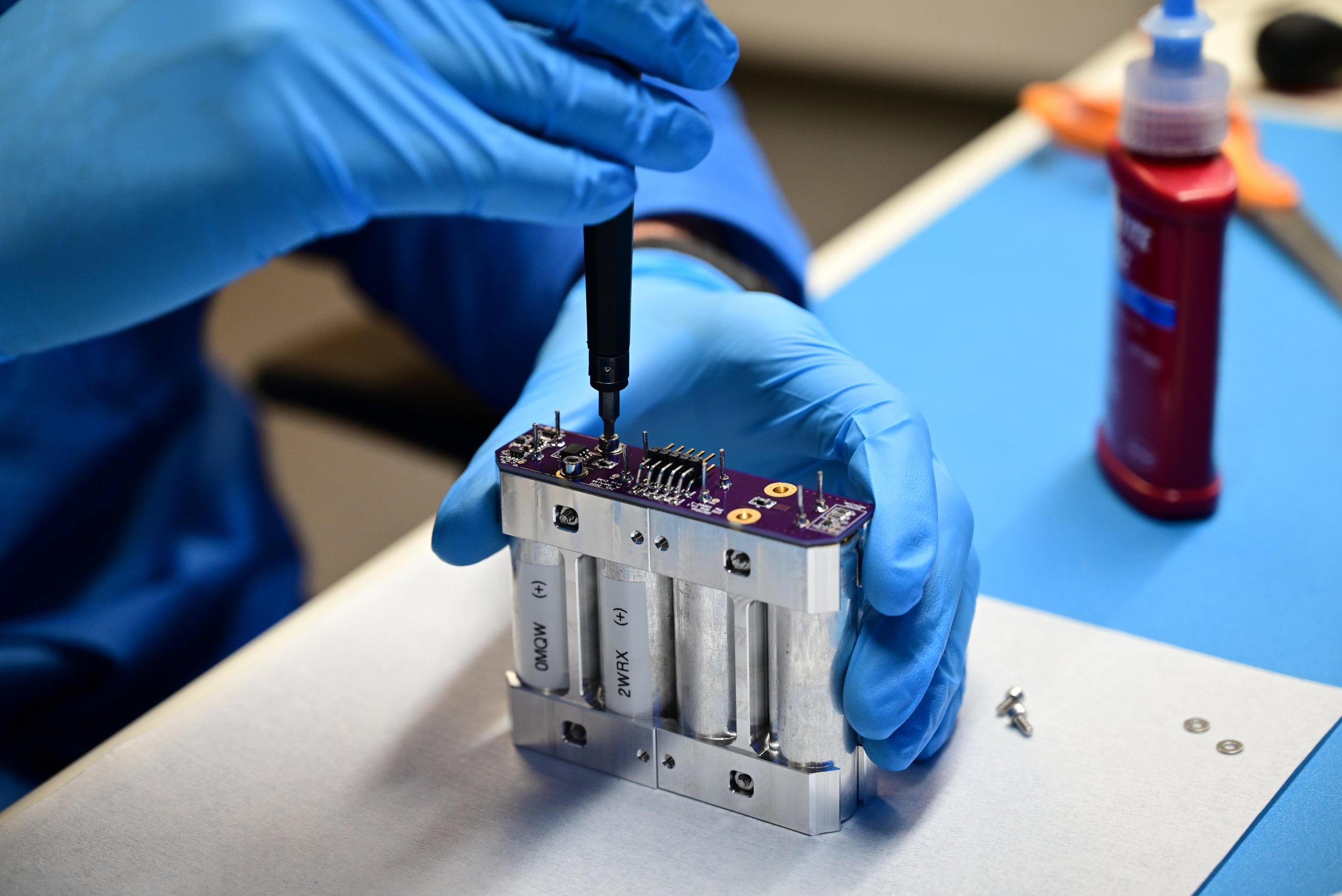

The ORCASat battery pack is special as it uses a novel battery chemistry that as far as we know, has never been used for spaceflight before. The battery pack along with the rest of the Electrical Power System is designed, manufactured, and tested in-house at UVic. The battery pack uses Lithium Titanium Oxide (LTO) cells, which offer several advantages over traditional Li-ion (LiCoO2) chemistries. The main advantage to LTO cells is that they can be charged and discharged at temperatures down to -30 °C with no permanent degradation of the cell. This allows the spacecraft to fly without a battery heater, which saves precious watts from the power budget. This design decision alone allows ORCASat to fly without deployable solar arrays which greatly reduces the system design complexity.

The trade off is that the cells have much lower energy density than most Li-ion chemistries, but with the maximum eclipse duration of ~ 38 minutes, the battery pack energy density is not a significant design constraint. The other difficulty is properly testing and characterizing these cells for spaceflight.

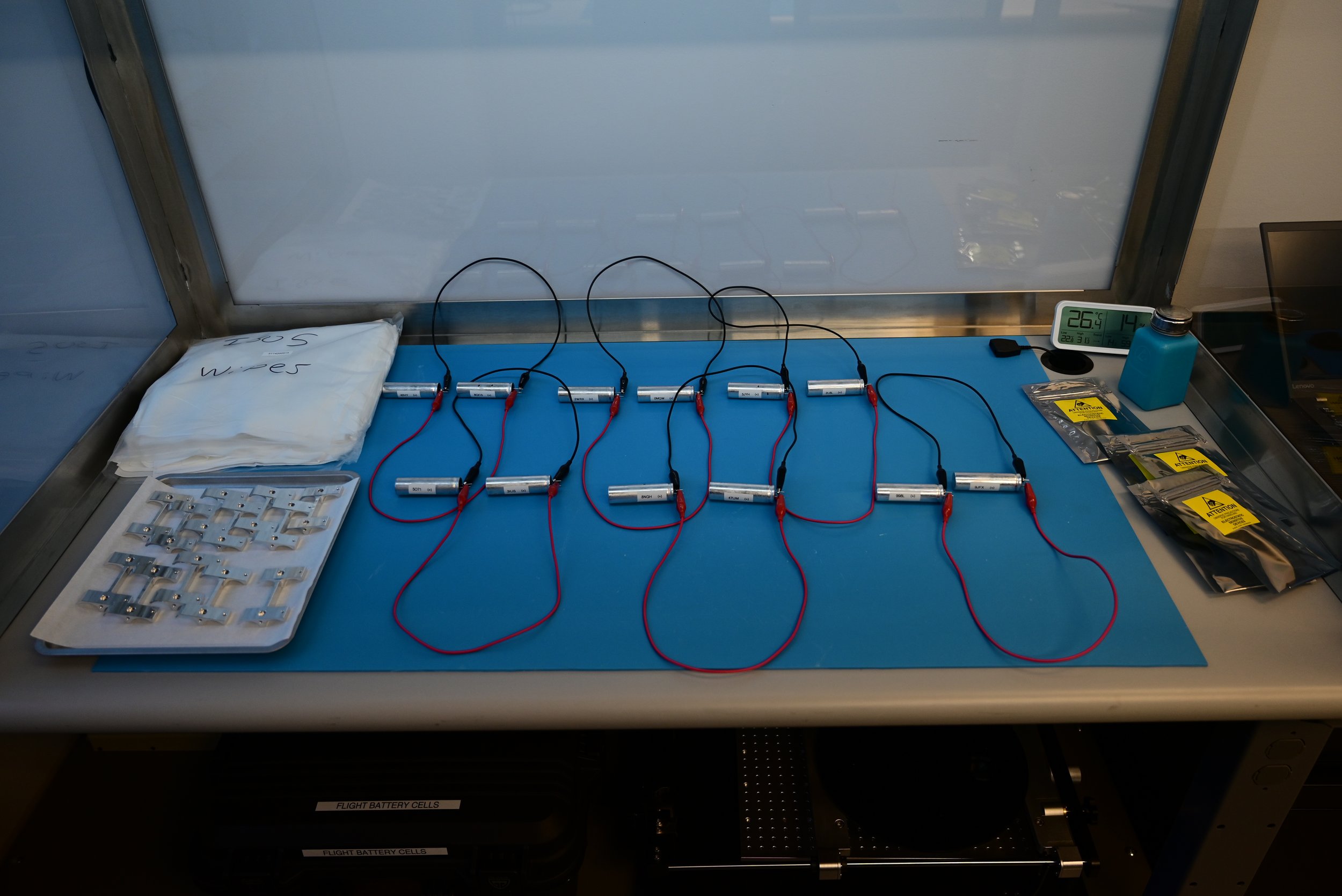

The assembly process is pretty easy due to the casing of the LTO cells. Instead of a leadless cylindrical cell like normal 18650 Li-ion cells, the LTO cells use a capacitor type casing with both leads on one end. This makes it easy as no tabs have to be spot welded or soldered on the cell. The assembly process mostly consists of testing each cell individually for capacity, internal resistance, and self discharge. Cells are matched into pairs based on internal resistance and balanced before the assembly. Once the pairs are balanced, they are assembled into a battery pack.